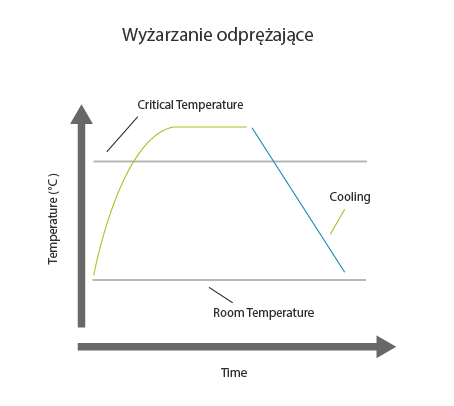

Stress relief annealing reduces residual stresses from manufacturing processes without changing the structure or properties of the material. This is done by heating the metal to a certain temperature and then cooling it in a controlled manner. This helps to remove any internal stresses caused by quenching or other manufacturing methods, thus avoiding potential future problems.

Stress relief annealing

Type of technology

Development phase

Level of innovation

Scale of production

mass

Technology readiness level TRL

Description of the technology

Purpose of use

reducing the internal stresses generated by the production process

Industry usage

reduction of internal stresses generated in manufacturing processes such as welding, cold forging, mechanical cutting, quenching

Alternative technologies

- none

Visualisation of action

Advantages

- reduction of internal stresses after manufacturing processes

- change in mechanical properties

- restoration of the material to its original state

Disadvantages

- requires precise temperature control

- long annealing time

Workpiece material types

- steel

Examples of products

- steel structures

- pipes

- tanks

- shafts

- gears

- sleeves

- lathe knives

Implementation of the technology

Required resources

- heating furnace

Required competences

- on-the-job training

Environmental aspects

Expert evaluation

Development centers

- AGH University of Krakow

- Institute of Metallurgy and Materials Science of Polish Academy of Sciences

- Warsaw University of Technology

- Cracow University of Technology

- Łukasiewicz – Upper Silesian Institute of Technology

- Czestochowa University of Technology

Legal conditions

- none