A heat treatment process in which a component is heated to an appropriate temperature (above the recrystallisation temperature but below the melting point), held at that temperature to homogenise and restructure it, and then rapidly cooled.

Quenching

pl.

Type of technology

Development phase

Level of innovation

Scale of production

mass

Technology readiness level TRL

Description of the technology

Purpose of use

increasing strength and hardness of the workpieces

Industry usage

automotive, tool industry

Alternative technologies

- none

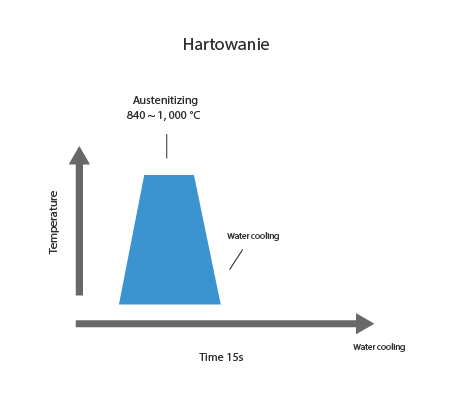

Visualisation of action

Advantages

- increases the hardness of the material

- improves the strength of the metal

- improves the wear resistance of the metal

- can improve the corrosion resistance of the metal

- can improve the electrical conductivity of the metal

Disadvantages

- can cause deformation of the metal

- can cause internal stresses that can lead to cracking

- can make the metal harder than necessary (making it more difficult to machine)

- can cause the metal to become brittle and crack more easily

Workpiece material types

- steel

Examples of products

- kitchen utensils

- automotive parts

- tools subject to heavy wear

- engineering parts that must withstand heavy loads

- brackets

- nuts

- bolts

- hooks

- nails

- screws

- hand tools (e.g. hammers and screwdrivers)

- springs

- bearings

Implementation of the technology

Required resources

- quenching furnace

- quenching bath

Required competences

- on-the-job training

Environmental aspects

Expert evaluation

Development centers

- AGH University of Krakow

- Institute of Metallurgy and Materials Science of Polish Academy of Sciences

- Warsaw University of Technology

- Cracow University of Technology

- Łukasiewicz – Upper Silesian Institute of Technology

- Czestochowa University of Technology

Legal conditions

- none