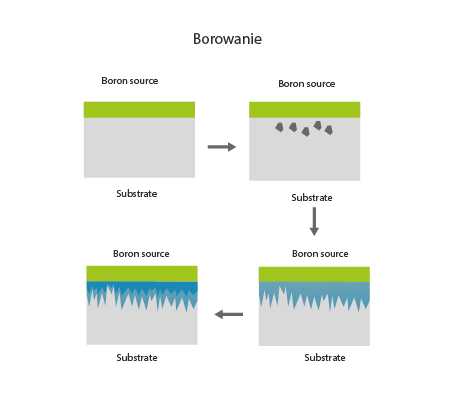

Boriding involves the diffusion of boron into the surface layer of the steel at a temperature of 800-1,100°C from a few to several hours. The boriding process is usually carried out using powders or pastes.

Boron adsorbed on the surface of the steel penetrates deep into the steel structure, forming a layer of boron with a characteristic needle-like structure. The thickness depends on the process temperature, the boriding method and the chemical composition of the steel. The resulting layers have considerable hardness, depending on the parameters of the boriding process.

Depending on the boron content of the steel surface layer, Fe2B and FeB boride phases are formed. The FeB boride layers achieve the highest hardness, oscillating in the range 2,000-2,400 HV, while the Fe2B layers have a slightly lower hardness of 1,600-2,000 HV.