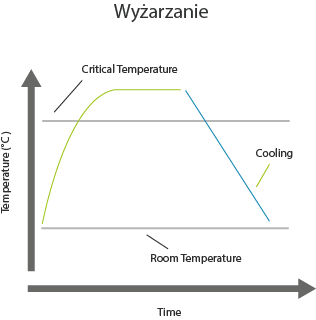

Annealing is a heat treatment process that changes the physical and sometimes chemical properties of a material. The annealing process involves heating the product to a temperature above the recrystallisation temperature, holding it at that temperature and then cooling it in a controlled manner. The rate of cooling depends on the type of metal being annealed. Steel is usually cooled in air, while copper, silver and brass can be cooled slowly in air or quenched rapidly in water.

Annealing

Type of technology

Development phase

Level of innovation

Scale of production

mass

Technology readiness level TRL

Description of the technology

Purpose of use

change in mechanical properties of the material/workpiece (improved plasticity at the expense of strength)

Industry usage

reproduction of uniform physical properties of materials/components previously subjected to other processing methods, e.g., plastic processing (stamping, drawing), machining (generating large amounts of heat or material displacement), welding (residual stresses of material exposed to elevated temperatures)

Alternative technologies

- none

Visualisation of action

Advantages

- improves workability of materials

- reduces hardness

- increases plasticity and machinability of materials

Disadvantages

- annealing time

Workpiece material types

- all material groups

- ferrous metals

- non-ferrous metals

- non-ferrous metals alloys

Examples of products

- steel pipes

- exhaust systems

- aluminum sheets

- wings

- fuselages

- rolled blades and knives

- copper wires

Implementation of the technology

Required resources

- heat furnaces

Required competences

- on-the-job training

Environmental aspects

Expert evaluation

Development centers

- AGH University of Krakow

- Institute of Metallurgy and Materials Science of Polish Academy of Sciences

- Warsaw University of Technology

- Cracow University of Technology

- Łukasiewicz – Upper Silesian Institute of Technology

- Czestochowa University of Technology

Legal conditions

- none