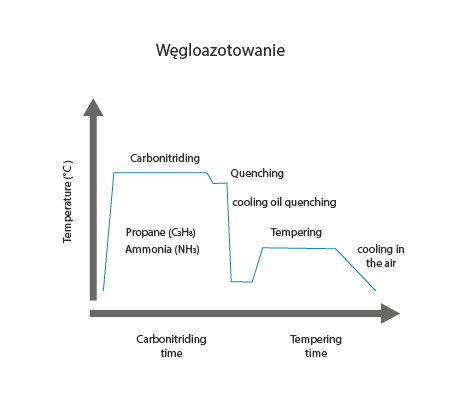

Carbonitriding (nitrocarburising) is one of the thermo-chemical processes for steel, in which the surface of steel objects is simultaneously saturated with carbon and nitrogen at temperatures ranging from 500 to 950°C. The application of heat treatment processes such as quenching and tempering produces a hard and wear-resistant surface layer. Depending on the nature of the substance releasing the carbon and nitrogen, the carbonitriding process can be carried out in bath or gaseous form.

Carbonitriding

Type of technology

Development phase

Level of innovation

Scale of production

mass

Technology readiness level TRL

Description of the technology

Purpose of use

change of the properties of materials through thermal and chemical processes

Industry usage

automotive, mechanical, tooling industries

Alternative technologies

- nitriding

- carburising

Visualisation of action

Advantages

- increased hardness of steel

Disadvantages

- high costs

Workpiece material types

- steel

Examples of products

- gears

- shafts

- pistons

- rollers

- bearings

- levers in hydraulic/pneumatic/mechanical systems

- dies for forging

- dies for stamping

Implementation of the technology

Required resources

- furnaces

- vacuum furnaces

Required competences

- knowledge of materials science

Environmental aspects

Expert evaluation

Development centers

- AGH University of Krakow

- Opole University of Technology

- Institute of Metallurgy and Materials Science of Polish Academy of Sciences

- Warsaw University of Technology

- Cracow University of Technology

Legal conditions

- none