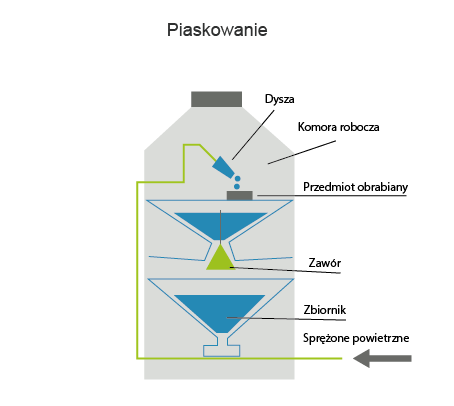

Sandblasting (abrasive blasting) is a method of abrasive machining using loose abrasives by the kinetic method. In sandblasting, abrasive grains are propelled in a high-speed fluid (gas, liquid or gas and liquid) stream. The abrasive grains are accelerated by the fluid stream at such a high speed that, despite their low mass, their kinetic energy is sufficient to perform the machining (breaking the cohesion of the workpiece material).

Sandblasting

pl.

Type of technology

Abrasive machining (by means of tools with undefined geometry)

Development phase

Level of innovation

Scale of production

batch, unit

Technology readiness level TRL

Description of the technology

Purpose of use

cleaning, levelling, protecting against corrosion or providing a suitable surface layer condition (e.g. roughness), often used to clean the surface of castings, forgings and objects after heat treatment

Industry usage

machine, automotive, aviation industries

Alternative technologies

- laser cleaning

Visualisation of action

Advantages

- fine cleaning of the surface of components of various dimensions (including very large ones)

- possibility of reconditioning steel components

- improvement of the fatigue strength of the product

- improvement of corrosion resistance

Disadvantages

- negative effects of the abrasive medium on the environment and people

- moderate durability of the sandblasting equipment (due to the dynamic effects of the abrasive particles)

- difficult process conditions for the machine operator

- the need to dispose of the abrasive medium

Workpiece material types

- steel

- non-ferrous metals

- non-ferrous metals alloys

Examples of products

- cleaning of metal structures

- preparation of metal surfaces for further processing

- car bodies

- balustrades

- steel structures

Implementation of the technology

Required resources

- sandblasting machine

- abrasives

Required competences

- training in finish machining

- extensive practical experience in abrasive machining processes

Environmental aspects

Expert evaluation

Development centers

Legal conditions

- none