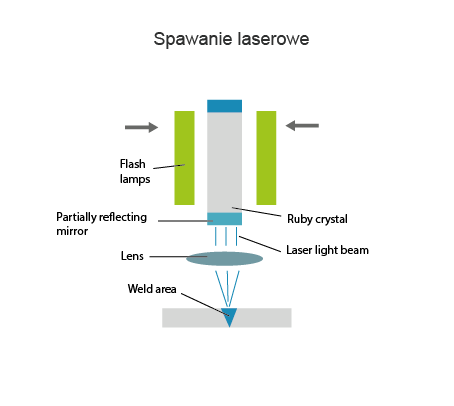

Laser beam welding is a welding process that uses a laser to join two metal parts together. The laser beams are directed into the cavity between the two metal parts to be joined. The laser beams have sufficient energy to generate heat when they strike the metal components, melting the material of the two metal components that fills the cavity. After cooling, a strong weld is formed between the two components.

This is a very efficient welding process that can be easily automated using robotic machines. This welding technique is most commonly used in the automotive industry.

Laser beam welding

Type of technology

Development phase

Level of innovation

Scale of production

mass

Technology readiness level TRL

Description of the technology

Purpose of use

joining various materials

Use in industry

automotive industry

Alternative technologies

Visualisation of action

Advantages

- high weld quality

- easy to automate and robotise

- no electrode is required

- the tool does not wear out as it is a non-contact process

- welding time for thick walls is reduced

- possibility to weld in hard-to-reach areas

- possibility to weld metals with different physical properties

- it does not produce any X-rays

- possibility of welding in air (no vacuum required)

Disadvantages

- expensive equipment

- high maintenance costs

- some metals may crack due to the rapid cooling

- operation of the laser requires highly skilled personnel

- weld thickness is limited to 19 mm

- the energy conversion efficiency of laser beam welding is very low

Workpiece material types

- all material groups

- ferrous metals

- non-ferrous metals

- non-ferrous metals alloys

Examples of products

- steel structures

- propellers

- rudders

Implementation of the technology

Required resources

- expensive welding equipment

Required competences

- training in technology

- training in the use of a laser welding machine

Environmental aspects

Expert evaluation

Development centers

- AGH University of Krakow

- Opole University of Technology

- Institute of Metallurgy and Materials Science of Polish Academy of Sciences

- Warsaw University of Technology

- Cracow University of Technology

Legal conditions

- none