Metal ageing is a process that can be natural or artificial (applied to metal alloys that have been heat-treated in solution).

Natural ageing occurs throughout the life of the metal alloy. During this process, supersaturated alloying elements in the metal alloy form so-called metal deposits. These deposits block dislocations in the material, increasing the strength and hardness of the metal alloy while reducing its plasticity.

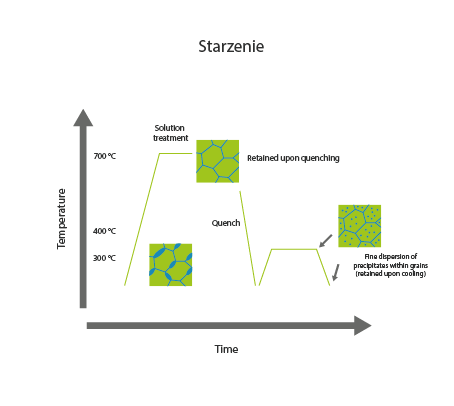

Artificial ageing is a process in which a material is subjected to heat treatment in solution, resulting in an acceleration of the rate of formation of deposits in the metal alloy, which are formed much faster than in natural ageing. Artificial ageing is achieved by raising the temperature of the metal alloy in solution to a point below its recrystallisation temperature, but high enough to accelerate the formation of deposits. Once the alloying element deposits have reached a suitable size, the metal alloy is rapidly cooled to prevent further changes to the metal deposits.