Nitriding is a thermochemical treatment process in which nitrogen is diffused into the surface of a metal to create a hardened surface. These processes are most commonly used on low-alloy steel. They are also used on titanium, aluminium and molybdenum.

Nitriding

Type of technology

Development phase

Level of innovation

Scale of production

mass

Technology readiness level TRL

Description of the technology

Purpose of use

increase in surface hardness, increase in abrasion resistance

Use in industry

aviation industry, defence industry

Alternative technologies

- carburising

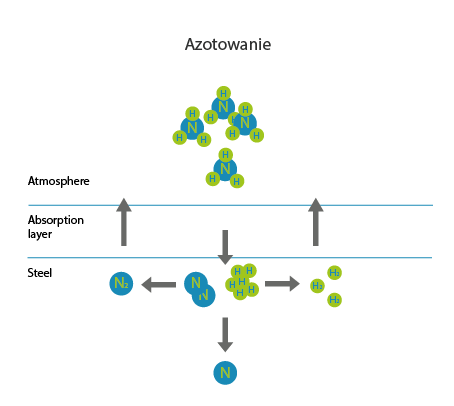

Visualisation of action

Advantages

- increased hardness

- increased fatigue strength and abrasion resistance

- relatively low cost

- improved corrosion resistance

Disadvantages

- only for ferromagnetic materials

- depending on the alloying element content

- low controllability of nitrogen penetration thicknesses into the material

- can result in increased roughness

Workpiece material types

- low-alloy steel

- alloy steel

- titanium

- aluminium

- molybdenum

Examples of products

- engine components

- structural components

Implementation of the technology

Required resources

- nitriding furnaces

Required competences

- training in furnace operation

Environmental aspects

Expert evaluation

Development centers

- AGH University of Krakow

- Opole University of Technology

- Institute of Metallurgy and Materials Science of Polish Academy of Sciences

- Warsaw University of Technology

- Cracow University of Technology

Legal conditions

- none