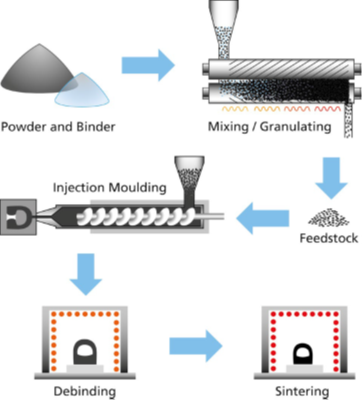

Metal Injection Moulding (MIM) is a process in which metal parts are produced by injecting a mixture of finely powdered metal and a binding material (binder/adhesive) into prepared molds and subsequently solidifying them.

The MIM process consists of the following steps:

1. Preparation of material

- Preparation of a mixture of powdered metal and a binder to produce a so-called feedstock. The final properties of the manufactured component depend on the properties of the prepared mixture.

- Granulation – the conversion of feedstock into pellets.

2. Injection molding – the injection of heated granules into previously prepared molds, in which the material under pressure takes on a specific shape (a process similar to plastic injection molding). The resulting component is also referred to as a “green component.”

3. Binder removal (debinding) – removal of bonding material from manufactured parts. The process yields porous metal parts prepared for sintering. The duration of the process depends on the thickness of the manufactured parts. Parts after the debinding process and before sintering are called “bronze parts.” As the binder is removed, the strength of the produced part decreases, so handling “bronze” parts requires great care.

There are the following methods of binder removal:

- Chemical – the soluble components of the binder are removed with a suitable solvent (e.g. hexane, heptane, acetone, water), the choice of which depends on the binder used. Usually carried out at room temperature. A type of chemical debinding is the catalytic decomposition of POM (polyoxymethylene/poly methylene oxide) raw material using gaseous nitric acid or oxalic acid.

- Thermal – the polymer binder is removed by placing the component in a furnace/chamber at an appropriate temperature, where the binder is extracted and vaporized in the presence of gas or under vacuum. Depending on the furnace used, it can be carried out in the same equipment as sintering.

4. Sintering – the purpose of the process is to change the internal microstructure of the part (removing pores formed during debinding). During sintering, the manufactured parts shrink to their final size, the overall density and strength are improved. The process is carried out at high temperature (below the melting point of the metal) in an inert atmosphere or using process gas or vacuum. After sintering, the part is considered finished.

5. Further processing of components (optional) – finished components produced by the MIM method can be subjected to further processing, e.g. heat treatment (including hardening, tempering), machining (e.g. drilling), etc.

MIM technology is considered very efficient and innovative. It allows the production of components with high precision and excellent mechanical properties with minimal waste and operating costs. The technology is widely used in various industries, making it very versatile.

Manufacturing parts using metal injection molding technology requires solvents and other methods of binder removal. Their selection should take into account the safety of workers and the environment. The use of MIM also requires the monitoring and control of process gas and chemical waste emissions to minimize their impact on the environment.

Source of process visualization: https://pl.linkedin.com/pulse/technologia-mim-nowo%C5%9B%C4%87-od-40-lat-micha%C5%82-maria%C5%84ski