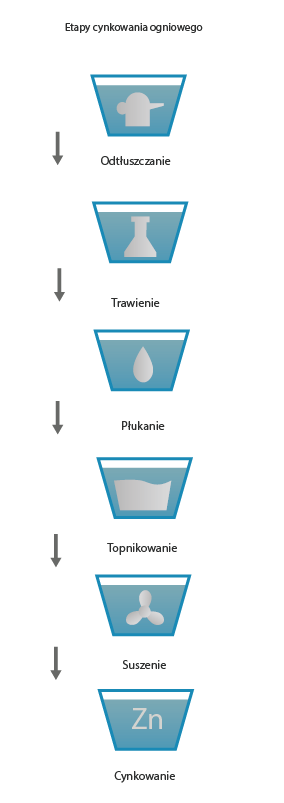

Hot-dip galvanising is the process of applying a thin layer of zinc to a workpiece.

The first preparatory step in the process is cleaning and degreasing the workpiece by shot blasting or vibratory grinding so that the surface is free from sand, rust, remnants of previous coatings or traces of gas corrosion. If this is not sufficient, the material should be flux-treated by bathing in a solution of zinc chloride and ammonium chloride, which will remove any residual oxides. The final stage of preparation is drying at temperatures above 100 degrees Celsius.

After these preparations, the workpiece is immersed in a liquid zinc bath heated to approximately 450 degrees Celsius. This allows an immediate reaction between the zinc and iron, resulting in an alloy layer on the surface of the part. After a few minutes, the part is removed from the bath and dried.