Galvanisation is the thermochemical process of coating the surface of steel objects with a layer of zinc. It prevents corrosion. It consists in the creation of a protective anodic layer on the surface of the steel object.

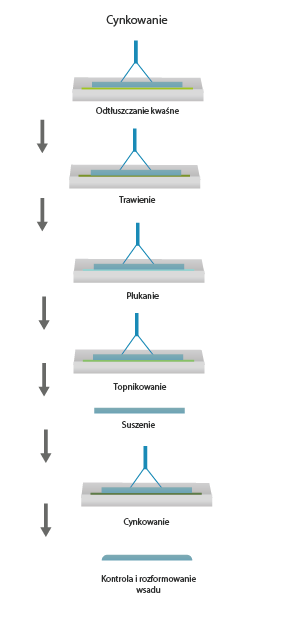

Galvanisation

Type of technology

Development phase

Level of innovation

Scale of production

mass

Technology readiness level TRL

Description of the technology

Purpose of use

improving the corrosion resistance of steel surfaces

Use in industry

metallurgy, automotive, aircraft, construction industries

Alternative technologies

- painting

Visualisation of action

Advantages

- protects metal from corrosion

- increases component life

- resistance to acidic substances

Disadvantages

- can be removed with a magnet

- the galvanised coating is prone to chipping and creating an uneven surface

- galvanised surfaces are very hard and durable making them unsuitable for applications where flexibility is required

- unweldable zinc coating

Workpiece material types

- steel

- cast iron

Examples of products

- pipes

- steel structures

- tanks

- steel sheets

- steel tapes

Implementation of the technology

Required resources

- galvanising line

Required competences

- none

Environmental aspects

Expert evaluation

Development centers

- AGH University of Krakow

- Opole University of Technology

- Institute of Metallurgy and Materials Science of Polish Academy of Sciences

- Warsaw University of Technology

- Cracow University of Technology

Legal conditions

- none