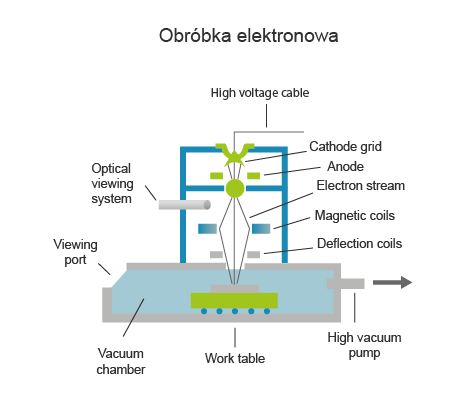

Electron beam machining is a machining process that uses the vapourisation of workpiece material by a stream of electrons emitted from a suitably heated electrode-cathode under vacuum conditions. In the case of welding, the contact area of the workpieces to be joined is molten by the heat generated by bombarding them in a vacuum with a concentrated beam of high-energy electrons.

Electron beam machining

Type of technology

Development phase

Level of innovation

Scale of production

batch

Technology readiness level TRL

Description of the technology

Purpose of use

high-precision machining of very difficult-to-machine materials (e.g. stainless steels, nickel and cobalt alloys, titanium alloys) in various shapes, subtractive manufacturing of holes, cut-outs and profiles, possibility of machining miniature components, welding of components

Use in industry

aviation industry, automotive industry, mould and die production, precision mechanics

Alternative technologies

- laser beam machining

- plasma arc machining

- micromachining

- bonding/welding

- welding

Visualisation of action

Advantages

- possibility of more efficient machining of hard and brittle materials (compared to conventional machining)

- possibility of machining small holes with high dimensional accuracy (compared to conventional machining)

- little change in the mechanical properties and structure of the machined material (compared to plasma arc machining)

- possibility of obtaining low surface roughness and high dimensional accuracy of the machined parts (compared to conventional machining and plasma arc machining)

- welding process is performed without the use of a binder

Disadvantages

- relatively high investment and tooling costs

- need for highly skilled operators to operate the machining station

- inability to machine large workpieces

- relatively low volumetric efficiency of material removal (compared to alternative techniques)

- high power consumption

Workpiece material types

- stainless steel

- nickel alloys

- cobalt alloys

- titanium alloys

Examples of products

- aircraft engine components

- turbine blades

- specialized details for flight control systems

- details for the production of aircraft seats

- details for the production of shock absorbers

- brake booster components

- components for advanced measuring instruments

- injection mold details for the production of plastic components

Implementation of the technology

Required resources

- electron beam machine

- tooling

- vacuum pump

Required competences

- training in erosion machining and abrasive blasting

- training in CNC machine programming

- extensive practical experience in subtractive manufacturing

Environmental aspects

Expert evaluation

Development centers

- Warsaw University of Technology

Legal conditions

- none