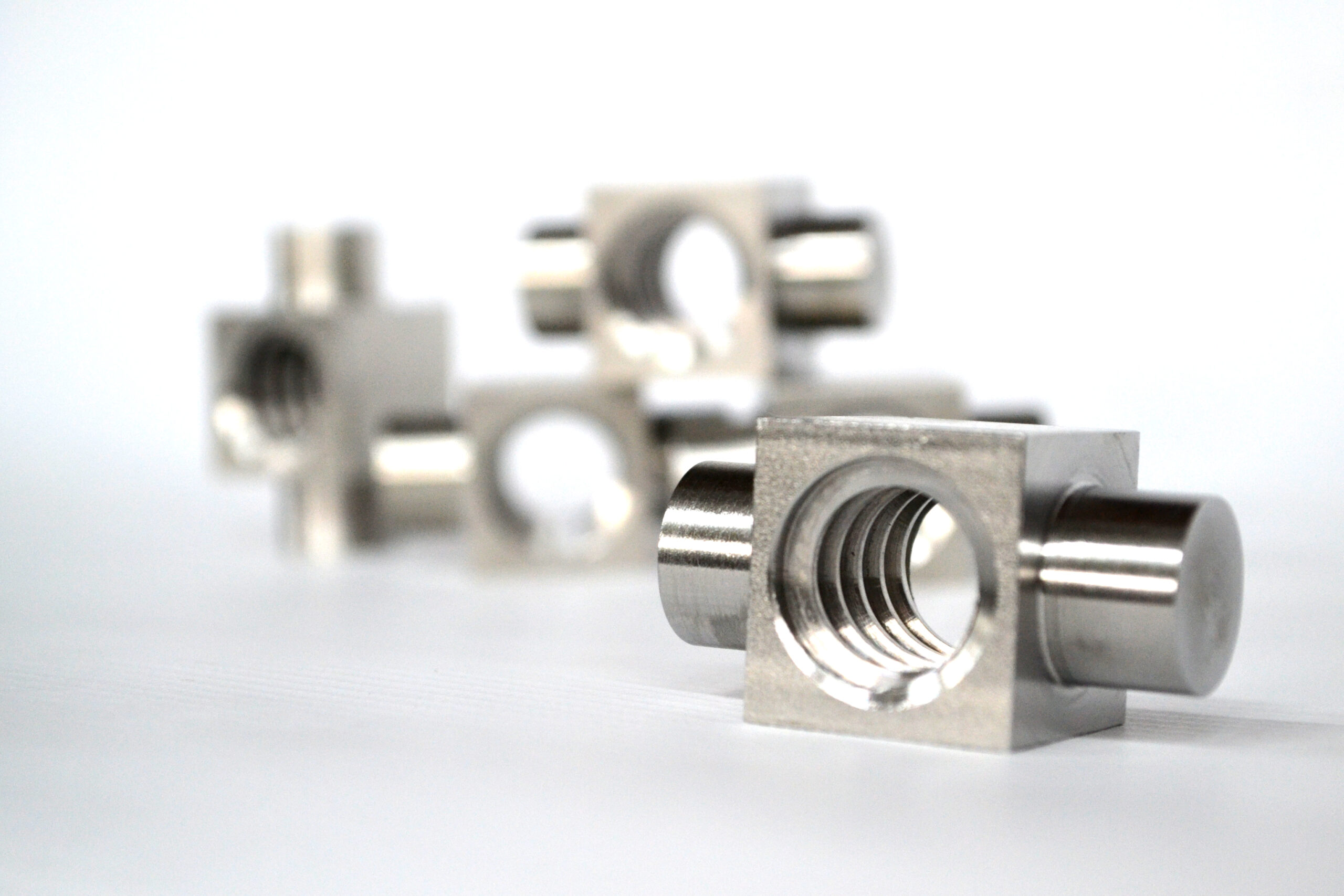

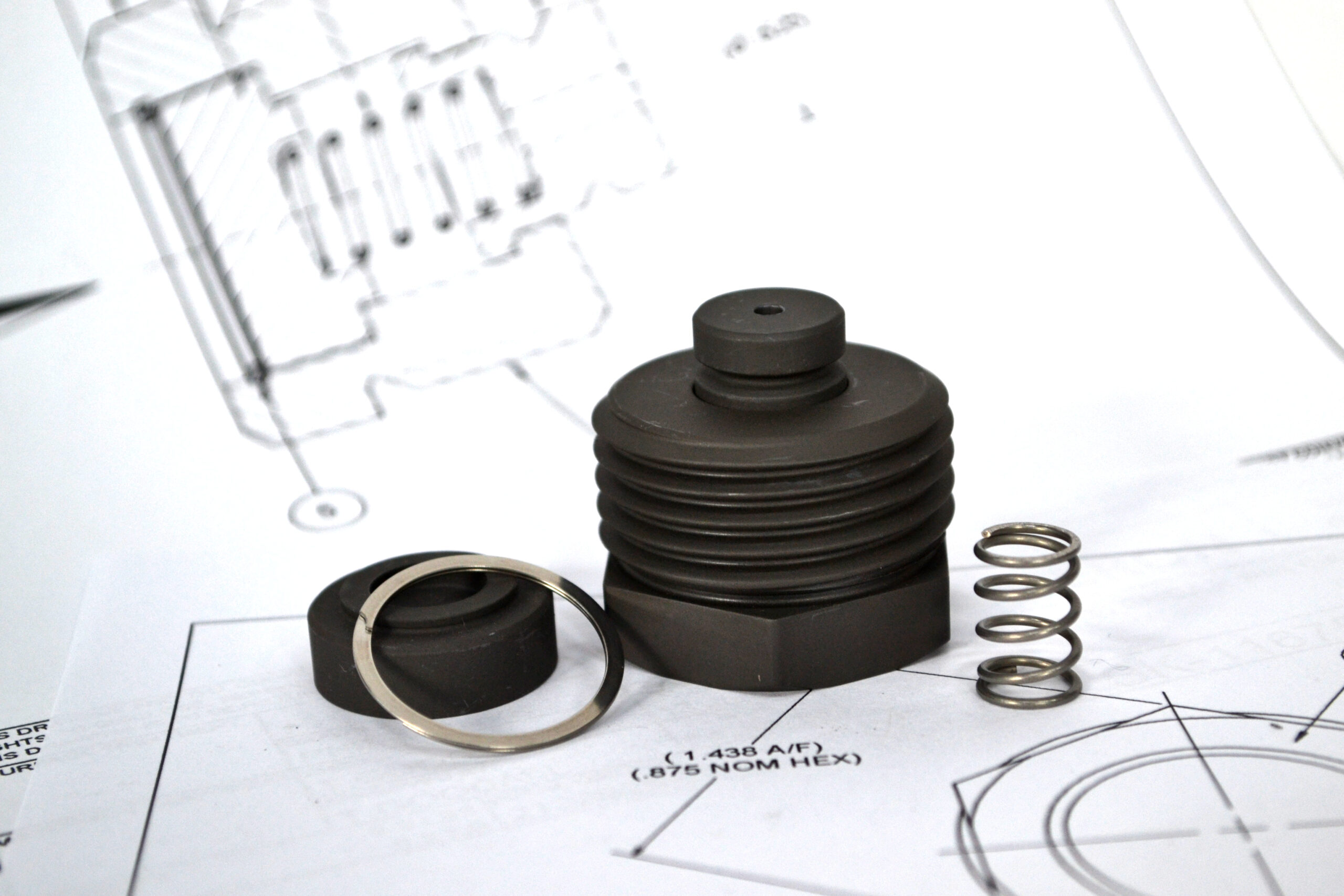

We specialise in the production of fasteners in a wide range of standards, strength grades and materials, as well as components made according to technical documentation. We carry out low-volume manufacturing tasks for specific dedicated construction projects with short lead times.

A functional machinery park allows the production of fasteners from high-quality alloy steels and a wide range of austenitic stainless steels, heat-resistant steels, hard-to-crack nickel alloys, light metals (including hydrostatically strengthened titanium and aluminium) and nonferrous metals, i.e. brass, copper and Aluminium Bronze. We manufacture our highly specialised fasteners according to DIN, ISO, ANSI, ASTM, ASME standards or according to graphical technical documentation.

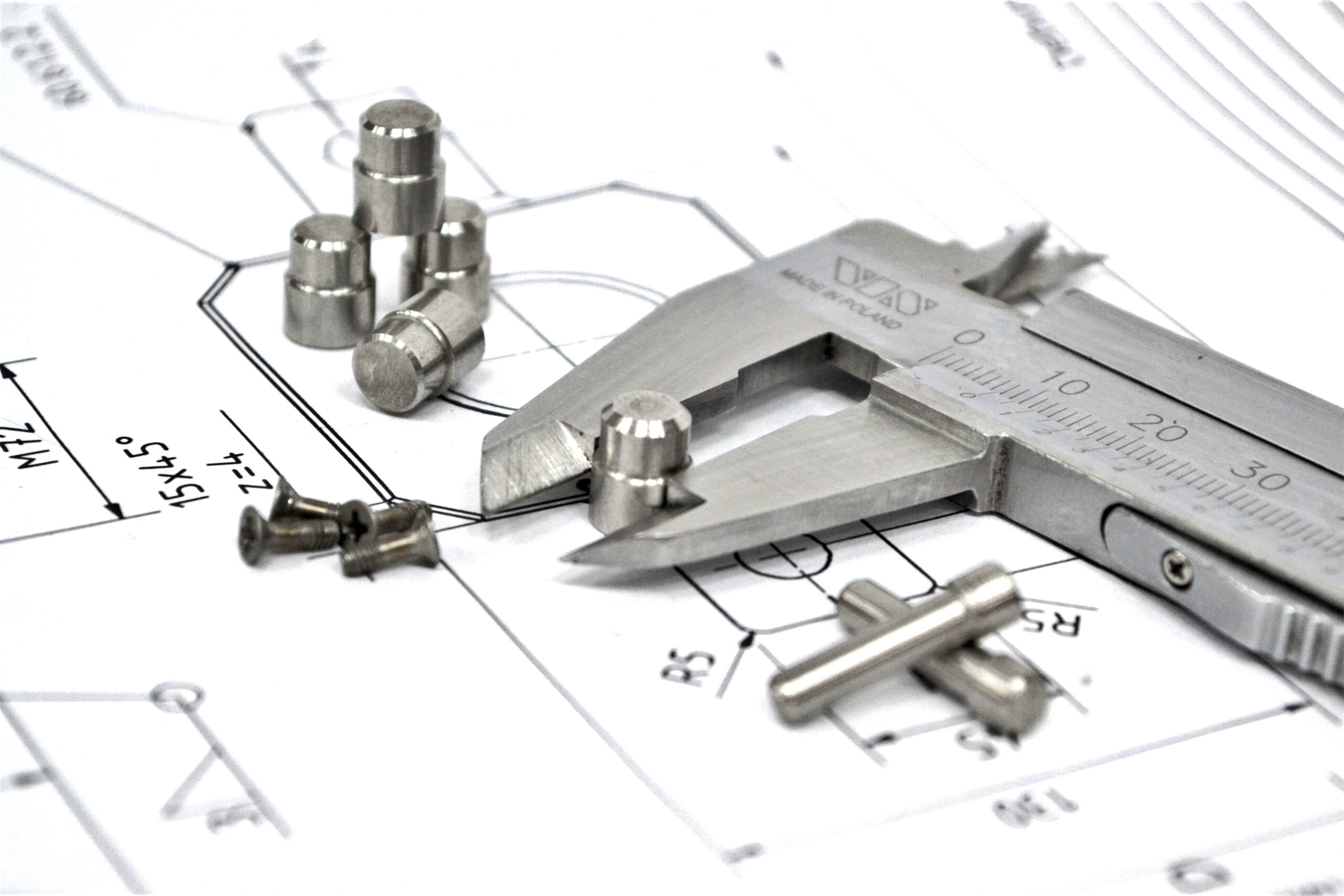

We have our own professional laboratory for strength testing and quality control. We perform testing of materials and finished products, including destructive testing (tensile strength and impact strength to -40°C).

All of our products are subject to strict quality control processes and can be delivered with 2.1, 2.2, 3.1 or 3.2 certifications according to EN-10204 (with the possibility of accreditation by DNV GL, Lloyd’s Register, ABS or Bureau Veritas).

We are also certified by TUV NORD Systems GmbH & Co. KG for the manufacture of fasteners for use in pressure equipment in accordance with the provisions of the PED 2014/68/EU Directive and AD 2000-W0 regulations.

All these opportunities create the conditions for a one-stop shop for fastener products. The guarantee of professional customer service and high quality products is our tradition and professional, highly qualified staff.